Introduction

Welcome to Green Genesis Engineering Limited (GGEL), the leading provider of cutting-edge Effluent Treatment Plants (ETP) in Bangladesh. With a steadfast commitment to customer satisfaction, GGEL delivers reliable and advanced wastewater treatment solutions. Our intricately designed ETP systems boast seamless operation, user-friendly interfaces, and efficient execution, setting the standard for innovation in the industry. Specializing in water treatment process integration, GGEL ensures optimal performance and user-friendliness. Our comprehensive offerings include versatile designs, cutting-edge technologies, and scalable solutions, all underscored by cost-effectiveness and a commitment to eco-friendly practices. With a consultative approach, GGEL collaborates closely with clients to ensure successful project outcomes. Choose GGEL for tailored, environmentally conscious effluent treatment solutions, exemplifying our dedication to sustainable wastewater treatment in Bangladesh. Proudly serving diverse industries, including Washing & Dying, Food & Beverage, Pharma, Leather, Paper, Sugar, Glass, Chemicals, and Fertilizers, GGEL prides itself on leveraging the latest and most advanced technologies for efficient and sustainable wastewater treatment.

What is an Effluent Treatment and Effluent Treatment Plant?

Effluent Treatment is a specialized method dedicated to purifying industrial wastewater, with the primary goal of enabling its safe reuse. This process aims to mitigate the environmental impact caused by harmful effluents, ensuring that the discharged water meets acceptable safety standards before being released into the environment.

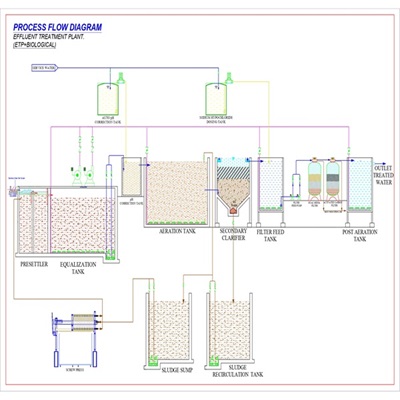

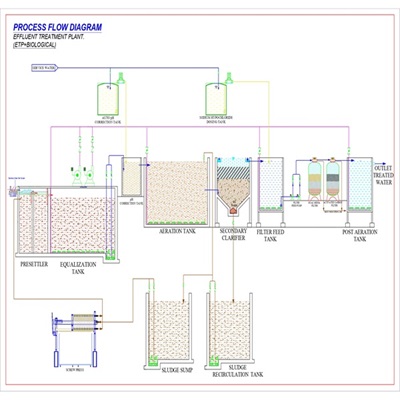

An Effluent Treatment Plants (ETP) is a specialized facility design to treat and purify industrial waste water before its safe discharge into the environment. Through a comprehensive approach, ETPs utilize a combination of physical, chemical, and biological processes to effectively eliminate contaminants from the wastewater, ensuring that it meets stringent environmental standards before being safely discharged into the ecosystem. By adopting these sophisticated treatment methods, ETPs not only facilitate compliance with regulatory frameworks but also mitigate potential adverse effects on ecosystems and public health.

How many levels of treatment are there in ETP?

The Effluent Treatment Plant (ETP) consists of three crucial treatment levels:

Primary Treatment Level:

The primary stage involves the removal of large solids and organic debris. Subsequently, chemical procedures such as flocculation and chemical coagulation are implemented to enhance water quality. pH control using HCl is applied for optimal conditions. In the dissolved air flotation stage, contaminants are separated.

Secondary Treatment Level:

This stage focuses on the biological treatment of wastewater, achievable under both aerobic and anaerobic conditions. This facilitates the decomposition of organic matter by microorganisms, playing a pivotal role in purifying the water.

Tertiary Treatment Level:

At the final stage, the wastewater undergoes meticulous cleaning before its release into the environment. Chlorine and alum are employed for treatment, effectively eliminating remaining inorganic compounds. Furthermore, this step ensures the removal of microorganisms, including bacteria, viruses, and various parasites, enhancing the overall purification process.

These comprehensive treatment levels collectively contribute to the efficient purification of wastewater, meeting environmental standards for safe discharge.

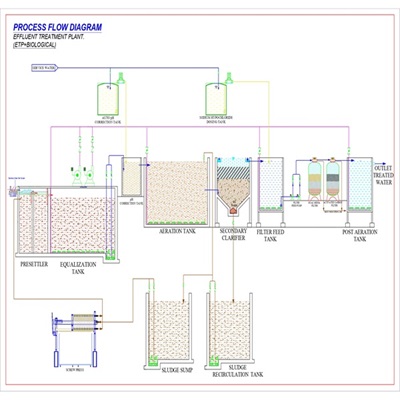

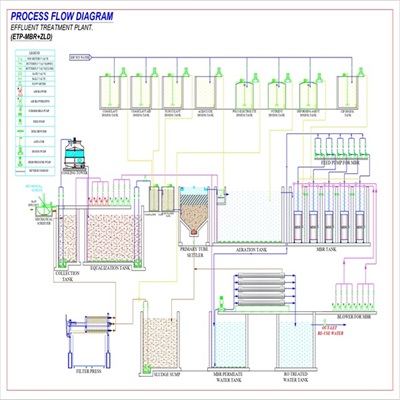

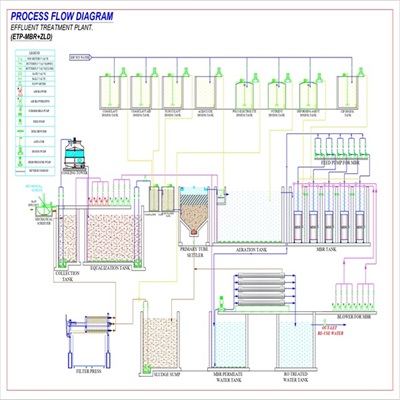

What are the different types of Effluent treatment plant?

Effluent treatment can be subdivided into three general processes.

- Chemical

- Physical

- Biological

Different Biological processes

- Moving Bed Biofilm Reactor (MBBR)

- Membrane Bio Reactor (MBR)

- Trickling Filter (TF) / (Attached Growth Biological System)

- Sequential Batch Reactor (SBR)

- Activated Sludge process (ASP)

- Rotating Bio Contactor/ Reactor (RBC)

What is the MBBR system used in effluent treatment plant?

The Moving Bed Biofilm Reactor (MBBR) system is a biological treatment process used in effluent treatment plants. Extended surface area plays a very important role in biofilm formation. Free-floating carriers allow biofilms to form on the surface, therefore a large internal surface area is crucial for contact with water, air, bacteria, and nutrients It employs aeration and a media-filled reactor to promote the growth of microorganisms that break down organic pollutants in wastewater. The “moving bed” refers to the constant agitation of plastic media within the reactor, providing a surface for the biofilm to develop. This enhances the treatment efficiency by increasing the contact between microorganisms and wastewater, leading to effective biological treatment of contaminants.

What are the advantages of the MBBR system in effluent treatment?

The advantages of the Moving Bed Biofilm Reactor (MBBR) system for effluent treatment include:

Space Efficiency: MBBR systems offer a compact design, making them suitable for locations with limited space.

High Treatment Efficiency: The dynamic environment created by the moving biofilm carriers maximizes contact between microorganisms and the effluent, leading to effective breakdown of organic pollutants.

Adaptability to Varying Loads: MBBR systems can handle fluctuations in effluent loads, providing flexibility in treating wastewater with different compositions.

Sustainable Treatment: The efficient microbial biofilm breakdown of pollutants contributes to a sustainable wastewater treatment process in Effluent Treatment Plants (ETPs).

Ease of Operation: MBBR systems are known for their ease of operation, making them practical for various industrial and municipal applications.

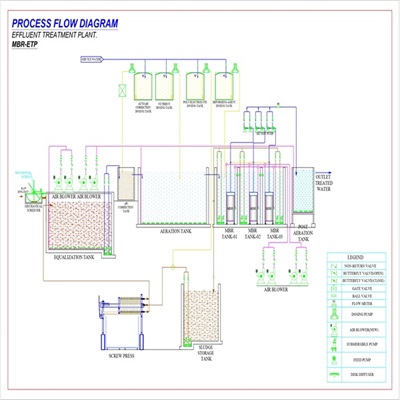

What is the MBR system used in effluent treatment plant?

In an Effluent Treatment Plant (ETP), the Membrane Bioreactor (MBR) system functions similarly to its application in wastewater treatment. It combines biological treatment with membrane filtration to break down organic pollutants. Microorganisms facilitate the treatment process, while membranes serve as a physical barrier, ensuring the removal of suspended solids and contaminants from the treated water. This technology is favored for its ability to provide high-effluent quality, occupy a smaller footprint, and enhance solids retention, making it valuable in municipal and industrial settings for water reclamation and meeting strict discharge standard.

What are the advantages of the MBR system in effluent treatment plant?

The advantages of the Membrane Bioreactor (MBR) system in effluent treatment include:

High-effluent Quality: MBR systems provide treated water with a high level of purity by effectively removing organic pollutants and contaminants.

Compact Footprint: MBR technology occupies a smaller space compared to conventional treatment methods, making it suitable for situations where space is limited.

Improved Solids Retention: The system enhances the retention of solids, ensuring more effective treatment and separation of impurities from the water.

Efficient Removal of Suspended Solids: Membranes act as a physical barrier, ensuring the efficient removal of suspended solids from the treated water.

Versatility: MBR systems are versatile and applicable in both municipal and industrial settings, addressing the diverse needs of effluent treatment.

Compliance with Strict Standards: The technology is capable of meeting stringent discharge standards, making it valuable for regulatory compliance in environmental management.

What are the Benefits of an Effluent Treatment Plant?

Ans: Effluent Treatment Plants (ETPs) offer several benefits:

Environmental Protection: ETPs reduce the impact of industrial activities on the environment by treating and purifying wastewater before it’s discharged, minimizing pollution of water bodies and soil.

Compliance with Regulations: They help industries adhere to environmental regulations and standards set by governmental bodies, avoiding penalties for non-compliance.

Resource Conservation: Some ETPs enable the recovery of valuable resources or water, promoting sustainability and reducing overall water usage.

Public Health Protection: By treating wastewater, ETPs prevent the spread of harmful pollutants, safeguarding public health and ecosystem integrity.

Reuse Possibilities: Treated effluent might be suitable for reuse within the industry or for irrigation, reducing the demand on freshwater resources.

Overall, ETPs play a crucial role in mitigating the environmental impact of industrial processes and promoting sustainable practices.

FREQUENTLY ASKED QUESTION (FAQ)

An ETP is a facility designed to treat industrial wastewater, known as effluent, to remove pollutants before discharge into the environment.

Effluent treatment is essential to prevent pollution and protect ecosystems by removing harmful substances from industrial wastewater.

Primary treatment involves physical separation, secondary treatment uses biological processes, and tertiary treatment further refines water quality.

Primary treatment involves the removal of large solids through processes like sedimentation or screening.

Secondary treatment uses biological methods, such as activated sludge or trickling filters, to break down organic pollutants in the wastewater.

Tertiary treatment aims to achieve higher water quality standards by removing remaining contaminants through processes like filtration or chemical treatment.

If the effluent in ETP is acidic then caustic soda (Sodium Hydroxide) is added to increase the pH and if the effluent is basic then hydrochloric acid or sulfuric acid is added to Main the pH of the ETP plant.

Sludge generated during the treatment process is often treated separately and can be used for purposes like land application or incineration.

ETPs play a crucial role in ensuring that industrial activities comply with environmental regulations by treating wastewater before discharge.

Challenges include optimizing treatment processes, managing variable influent characteristics, and meeting evolving environmental standards.

Regular monitoring, adopting advanced treatment technologies, and implementing water conservation practices can enhance ETP efficiency.

Inadequate treatment may lead to water pollution, harming aquatic ecosystems, and posing risks to human health downstream.

Yes, sustainable practices include energy-efficient technologies, recycling treated water for industrial processes, and minimizing the use of chemical additives.

Green Genesis Engineering Limited (GGEL) is a renowned and trusted supplier of Effluent Treatment Plants (ETPs) in Bangladesh. They are distinguished for their commitment to delivering high-performance solutions and ensuring customer satisfaction through advanced technology and reliable services.