Features

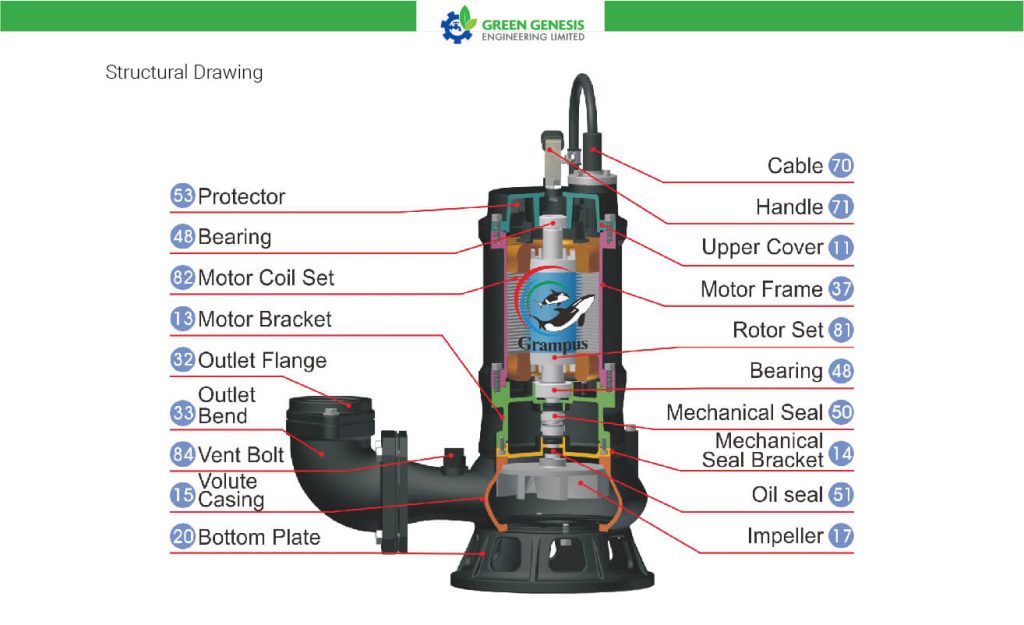

- Cable base and core wire are dealt with Epoxy Resin to avoid the moisture into the motor.

- Volute casing is equipped with the vortex impeller for drawing out mud and sewage effectively.

- Equipped with vent bolt at volute casing is to avoid air lock ensuring the pump operation steady.

- Equipped with a high-quality dual SIC mechanical seal.

- Motor is B class(130°C) insulation, enclosure IEC IP68.

- Auto-cut prevents the motor from overheating.

- Thick EPOXY coating is better than common painting in corrosion resistance and rust-resistance.

- This type can be equipped with a lift bracket.

Application

- Wastewater lift station, municipal wastewater treatment plant.

- Building a wastewater treatment system.

- Piggery excrement, animal & poultry farm.

- School, hospital, community wastewater treatment system.

- Food, paper, mining, textile, leather industry wastewater treatment system.

Material And Standard Table

| Calibar | 50mm, 80mm, 100mm | ||||||

| Liquid | Temperature | 0°C ̴ 40°C (32° ̴ 104 °F) | |||||

| Application | Available todeal with wastewater of building, sewer and industrial wastewater of food, paper, mining, textile, leather, dyeing and metal. | ||||||

| The lowest depth | 30 M | ||||||

| Pump | Structure | Impeller | Vortex Impeller | ||||

| Seal | Dual Mechanical Seal | ||||||

| Material | Upper Cover | FC- 200 | |||||

| Bearing | Heavy-duty bearing | ||||||

| Impeller | FC-200 | ||||||

| Volute Casing | FC-200 | ||||||

| Bottom Plate | 0.5- 1 HP: Engineering strength fiber reasin(STD) 2- 15 HP: FC: 200 | ||||||

| Motor Bracket | FC-200 | ||||||

| Mechanical Seal Bracket | FC-200 | ||||||

| Seal | Lubricant | ISO VG #32 | |||||

| Motor Side | Carbon/ Ceramic | ||||||

| Pump Side | Silicon Carbide/ Silicon Carbide | ||||||

| Motor | Type | Submersible dry type | |||||

| Insulation class | B class (130°C)/ F class(7.5- 15 HP) | ||||||

| Inner protector | Auto Reset Motor Protector | ||||||

| Material | Casing | FC-200 | |||||

| Main Shaft | SUS-410/ SUS-420 | ||||||

| Cable | Standard VCT | ||||||

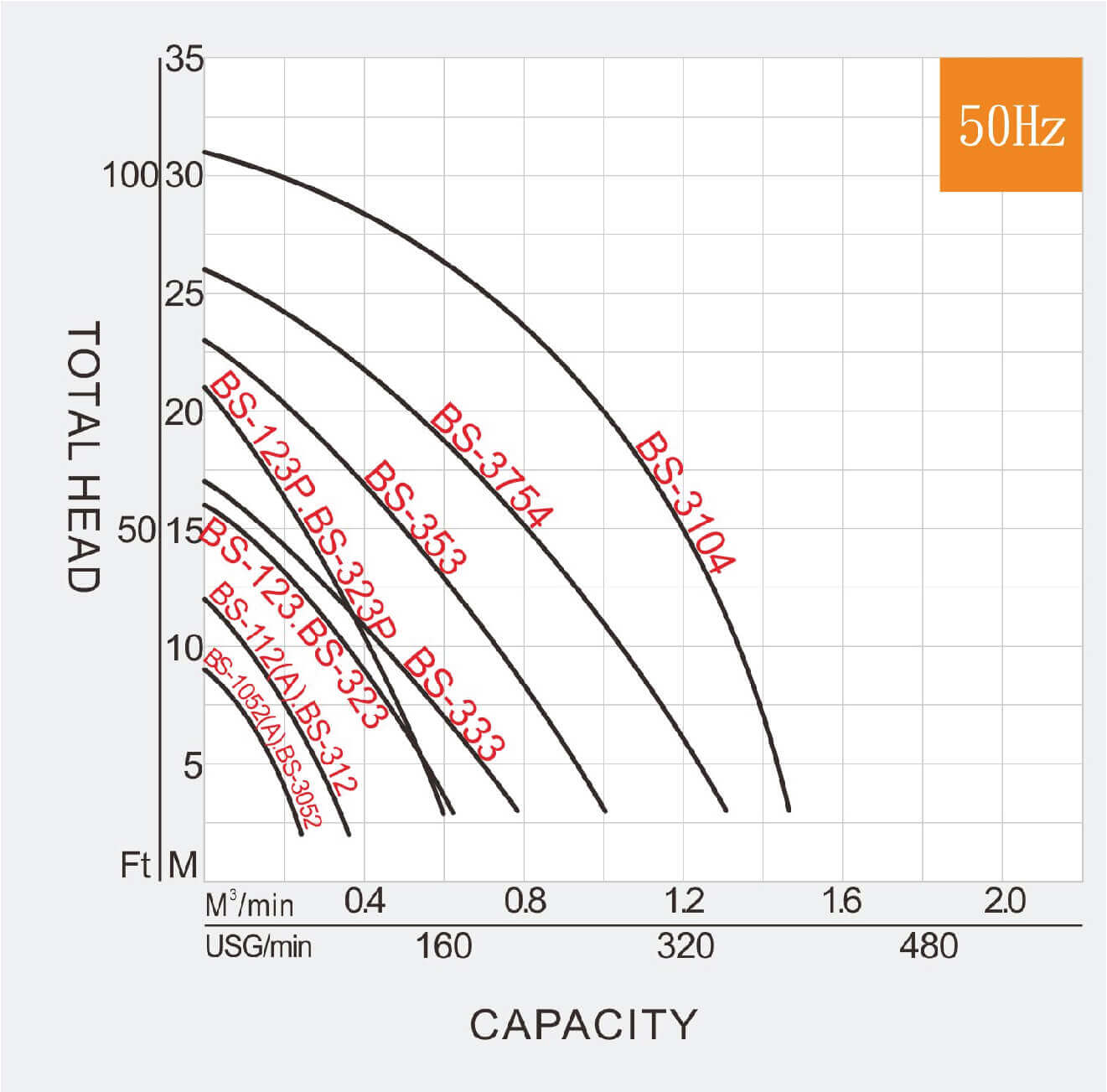

Performance Curve

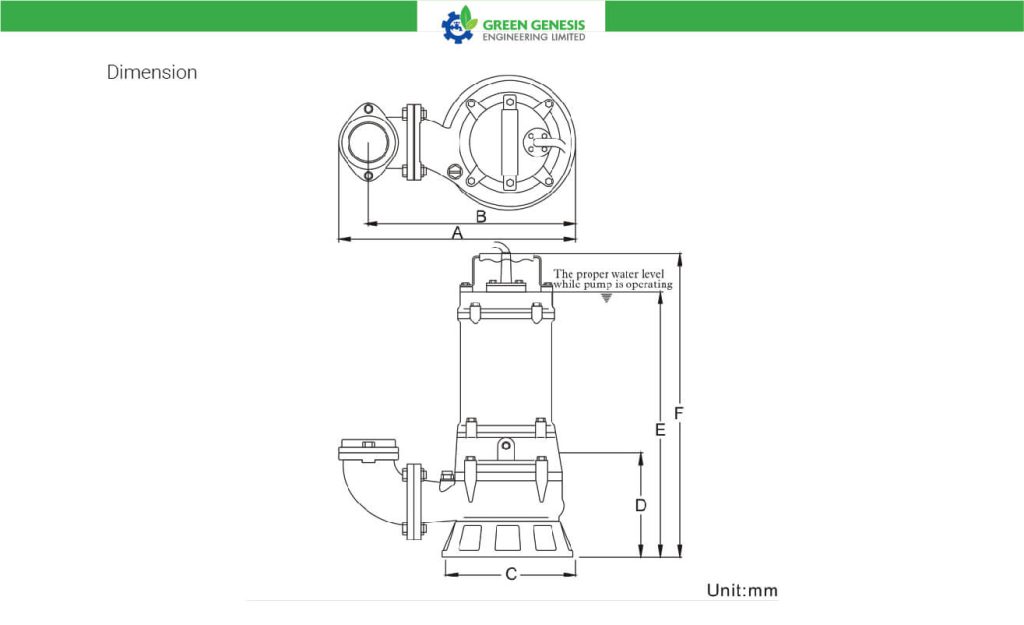

| Type | A | B | C | D | E | F |

| BS-1052 | 230 | 200 | 170 | 130 | 355 | 410 |

| BS-3052 | 230 | 200 | 170 | 130 | 355 | 410 |

| BS-112 | 230 | 200 | 170 | 130 | 390 | 440 |

| BS-312 | 230 | 200 | 170 | 130 | 390 | 440 |

| BS-123 | 410 | 355 | 220 | 200 | 520 | 590 |

| BS-323 | 405 | 350 | 220 | 200 | 470 | 540 |

| BS-333 | 445 | 390 | 250 | 200 | 470 | 540 |

| BS-353 | 460 | 405 | 250 | 205 | 490 | 560 |

| BS-3754 | 550 | 445 | 250 | 225 | 510 | 580 |

| BS-3104 | 550 | 445 | 250 | 230 | 530 | 600 |

| Type | Frequency | Phase | Power | Discharge | Ploe/Rotation | Std. Head | Std. Flow | Max. Head | Max. Flow | BS Weight | TOS-BS Weight | Solid Passage | ||||

| Hz | PH | HP | KW | Inch | mm | P/rpm | M | M3/min | M | M3/min | KG | mm | ||||

| BS-1052(A) | 50 | 1Φ | 0.5 | 0.4 | 2" | 50 | 2P/2850 | 4 | 0.2 | 9 | 0.27 | 18 | 27 | 35 | ||

| BS-3052 | 50 | 3Φ | 0.5 | 0.4 | 2" | 50 | 2P/2850 | 4 | 0.2 | 9 | 0.27 | 18 | 27 | 35 | ||

| BS-112(A) | 50 | 1Φ | 1 | 0.75 | 2" | 50 | 2P/2850 | 7.5 | 0.2 | 12 | 0.4 | 21 | 30 | 35 | ||

| BS-312 | 50 | 3Φ | 1 | 0.75 | 2" | 50 | 2P/2850 | 7.5 | 0.2 | 12 | 0.4 | 21 | 30 | 35 | ||

| BS-123 | 50 | 1Φ | 2 | 1.5 | 3" | 80 | 2P/2850 | 6.5 | 0.5 | 16 | 0.7 | 40 | 60 | 40 | ||

| BS-323 | 50 | 3Φ | 2 | 1.5 | 3" | 80 | 2P/2850 | 6.5 | 0.5 | 16 | 0.7 | 38 | 58 | 40 | ||

| BS-123P | 50 | 1Φ | 2 | 1.5 | 3" | 80 | 2P/2850 | 7 | 0.5 | 21 | 0.65 | 40 | 60 | 32 | ||

| BS-323P | 50 | 3Φ | 2 | 1.5 | 3" | 80 | 2P/2850 | 7 | 0.5 | 21 | 0.65 | 38 | 58 | 32 | ||

| BS-333 | 50 | 3Φ | 3 | 2.2 | 3" | 80 | 2P/2850 | 9 | 0.5 | 17 | 0.9 | 43 | 63 | 45 | ||

| BS-353 | 50 | 3Φ | 5 | 3.7 | 3" | 80 | 2P/2850 | 15 | 0.5 | 23 | 1.1 | 47 | 67 | 40 | ||

| BS-3754 | 50 | 3Φ | 7.5 | 5.5 | 4" | 100 | 2P/2850 | 11 | 1 | 26 | 1.4 | 58 | 78 | 50 | ||

| BS-3104 | 50 | 3Φ | 10 | 7.5 | 4" | 100 | 2P/2850 | 20 | 1 | 31 | 1.5 | 63 | 83 | 50 | ||