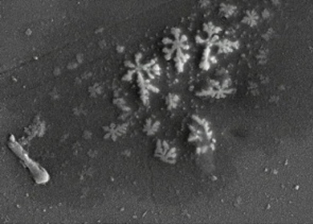

RO Membrane Fouling

Prevention and Removal

Causes of RO Membrane Scaling and Fouling often depend of Pre-Treatment, most of the cases the effect can be controlled by proper Antiscalant selection and proper dosage Here we like to recommend Genesys speciality cleaning products for the successful removal of foulants from your RO Membrane, however it is important to apply the cleaning products correctly.

| Foulants | Information | Antiscalant | Cleaners |

|---|---|---|---|

|

Biofouling - accumulation of microorganisms such as bacteria, algae, and fungi on the membrane surface, resulting in the formation of biofilms. Specialist attention should be paid to alkaline cleaning, antiscalant selection, pre-treatment and shut down procedures. | Genesys LF - does not act as a nutrient source | Prevention: Genesol 30, 32 biocides, Removal: Genesol 40, Genesol 704, Genesol 734 & 764 |

|

Iron - common type of foulant found on membrane surfaces. Sources of iron include naturally occurring iron in most feed waters, overdosing of ferric based coagulants and corrosion products from distribution systems. | Genesys LF - will sequester iron | Genesol 38 & Genesol 721 |

|

Alumino-silicate (clay) - naturally occurring colloidal particles, which have not been removed by the pre-treatment system. Difficult to remove from lead elements due to impermeability. | N/A | Genesol 704, 734 & 764 difficult to remove, consult Genesys for procedure design |

|

Aluminium - membrane fouling can often occur as a result of excessive dosing of aluminium coagulants and poor operation of the filtration system. It is very difficult to remove from the membrane surface. | Genesys LF - will sequester aluminium ions | Special conditions of pH required, Genesol 34 and 36 - consult Genesys for detailed protocol |

|

Manganese - less common than iron fouling. When water containing manganese is oxidised, insoluble colloidal hydroxide particles are formed. | Genesys LF will sequester manganese | Genesol 38 & 40 |

Happy Clients Say

The process of Packaged STP is depending of characteristic of sewage however we are describing the typical process of Package STP in follows:

Their services are among the best to be honest. Making everything simple and easy, even for beginners and novices like me and my wife.

Founder Xcompany

Bryan Freeman

Their services are among the best to be honest. Making everything simple and easy, even for beginners and novices like me and my wife.

Director

Bryan Freeman 2

F.A.Q

The process of Packaged STP is depending of characteristic of sewage however

The foulants (including organics, colloids, cells, sludge flocs, and salts) interact with the membrane surface to decrease flux and increase operating costs.

Depending on the type of foulant on the membrane, RO membranes are generally cleaned at low and high pH. Low-pH cleaners are best for removing scale minerals and inorganic colloidal material, while high-pH cleaners are best for removing organics and biofouling.

Filtration membranes become fouled when contaminants accumulate on their surface or in their pores. As a result of foulants, water cannot pass through the membrane, resulting in higher hydraulic resistance, increased energy consumption, and even damage to the membrane and other components of the system.