RO Membrane Scaling

Prevention and removal

Nature of Feel Water of RO plants are not same always. All kinds of RO Plant’s feed waters are different in types of composition. As a result, different types of scale can be deposited on the RO membranes. if you cannot select correct Genesys Antiscalant that will be used, you will not get perfect result. Selecting the right Reverse Osmosis Genesys Antiscalant and Genesys Cleaning chemicals will optimize operating efficiency and help to prevent plant failure.

| Scale Species | Information | Antiscalant | Cleaners |

|---|---|---|---|

|

Calcium Carbonate is the most common scale found in membranes. Appears as an off white powder. Easily cleaned with a strong acid product. | Genesys LF | Genesol 37 and 38 |

|

Silica - can be present on a membrane as colloids, aluminosilicates on the lead membrane elements, or as scale on the final elements. Both forms are difficult to remove, being dependent on pH and temperature. | Genesys SI | Genesol 40 or 703, depending on colloidal or silica scale |

|

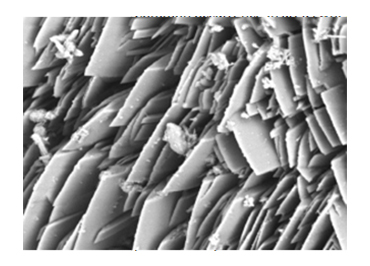

Calcium sulphate (gypsum) - crystalline structure with very sharp blade-like features, which cut the membrane surface. Common occurrence in areas where there is a natural sulphate content in the underlying geology. This makes it very difficult to clean. | Genesys CAS | Genesol 50, 34 and 703 Difficult to clean - ask us for advice on cleaning protocol design |

|

Calcium phosphate - appears in many forms. Commonly found in RO membrane systems fed with waste water or agricultural leachate, due to the high phosphate loading. | Genesys PHO | Genesol 37 and 38 |

|

Magnesium hydroxide (brucite) - precipitates at high pH, above 9.5, in membrane systems. Can be found in second pass elevated pH brackish water boron rejection plants, where pH levels are increased above 9.5 with sodium hydroxide to aid boron rejection. Relatively rare. | Genesys MG | Genesol 37 and 38 |

|

Barium sulphate (barite) - appears as white crystals, which can take on-blade like formations. Very difficult to clean effectively. | Genesys BS | Genesol 50 and 34 Difficult to clean - ask us for advice on cleaning protocol design |

|

Strontium sulphate (celestine) - appears as crystals or as needles, which can damage the membrane surface. Very difficult to remove. | Genesys CAS | Genesol 50 and 34 Difficult to clean - ask us for advice on cleaning protocol design |

Happy Clients Say

The process of Packaged STP is depending of characteristic of sewage however we are describing the typical process of Package STP in follows:

Their services are among the best to be honest. Making everything simple and easy, even for beginners and novices like me and my wife.

Founder Xcompany

Bryan Freeman

Their services are among the best to be honest. Making everything simple and easy, even for beginners and novices like me and my wife.

Director

Bryan Freeman 2

F.A.Q

RO Membrane Scaling

RO membrane scaling refers to the accumulation of mineral deposits or other substances on the surface of the Reverse Osmosis (RO) membrane, which reduces its effectiveness in removing contaminants from the water. The scaling occurs due to the precipitation of minerals from the water that passes through the membrane, leading to the formation of a layer of deposits on the surface of the membrane. The scaling can significantly reduce the water flow through the membrane and increase the pressure drop, ultimately leading to the need for replacement or cleaning of the membrane.

RO membrane scaling can occur due to several reasons. One of the most common causes is the presence of high concentrations of minerals such as calcium, magnesium, and silica in the water. When the concentration of these minerals exceeds their solubility limit, they can form solid deposits on the surface of the membrane. Other causes of scaling include high pH, temperature, and pressure of the water passing through the membrane, as well as the presence of organic and biological matter.

Preventing RO membrane scaling requires a combination of effective pretreatment and regular maintenance of the system. The pretreatment involves the removal of any suspended solids, organic matter, and chlorine from the water before it passes through the RO membrane. This can be achieved through various methods such as sediment filters, activated carbon filters, and anti-scaling agents. Regular maintenance involves monitoring the water quality, cleaning the membrane when necessary, and replacing any damaged or worn-out parts of the system.

Cleaning a scaled RO membrane requires careful consideration of the cause and severity of the scaling. There are several methods for cleaning a scaled membrane, including chemical cleaning, mechanical cleaning, and high-pressure cleaning. Chemical cleaning involves the use of specific chemicals to dissolve and remove the scaling. Mechanical cleaning involves physically scrubbing the surface of the membrane to remove the scaling, while high-pressure cleaning uses a high-pressure stream of water to remove the scaling.