Waste Water Treatment Plant in Bangladesh

Wastewater treatment plants (WWTP) in Bangladesh are essential components of the country’s efforts to manage water resources, combat pollution, and ensure public health. With a growing population, rapid urbanization, and increasing industrialization, these treatment facilities play a crucial role in purifying sewage and industrial effluents before their discharge into water bodies. Various technologies are employed in these plants to effectively treat different types of wastewater and address specific pollutants.

Conventional Treatment Methods:

Conventional wastewater treatment methods involve a series of physical, chemical, and biological processes. These processes typically include:

Primary Treatment: In this phase, large solid particles are removed from the wastewater through sedimentation. The water is allowed to settle, and the solids, referred to as sludge, are separated from the liquid.

Secondary Treatment: Biological processes are employed to break down organic matter present in the wastewater. Microorganisms, often bacteria, are introduced to consume and digest the organic pollutants. Common secondary treatment methods include activated sludge systems, trickling filters, and rotating biological contactors.

Tertiary Treatment: This stage focuses on further polishing the effluent to meet specific water quality standards. Tertiary treatment processes may include additional filtration, chemical treatment, and disinfection methods.

Advanced Treatment Technologies:

Beyond conventional methods, wastewater treatment in Bangladesh also utilizes advanced technologies to achieve higher treatment efficiency and address specific challenges:

Moving Bed Biofilm Reactor (MBBR): is a biological wastewater treatment technology that utilizes plastic biofilm carriers to foster the growth of microorganisms. These carriers move freely in the reactor, providing a large surface area for the microbes to attach and treat organic pollutants. Aeration supports aerobic microbial activity, and the system’s flexibility and compact design make it effective for municipal and industrial wastewater treatment. MBBR systems are known for high treatment efficiency, adaptability to changing conditions, and low sludge production.

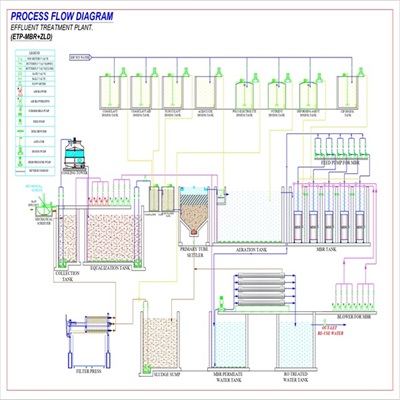

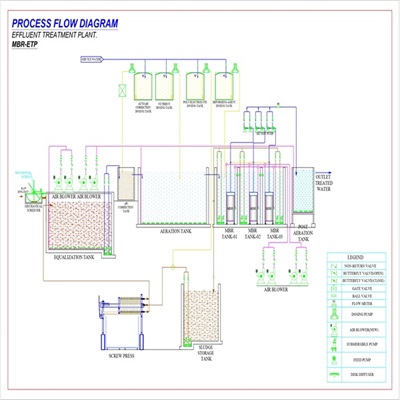

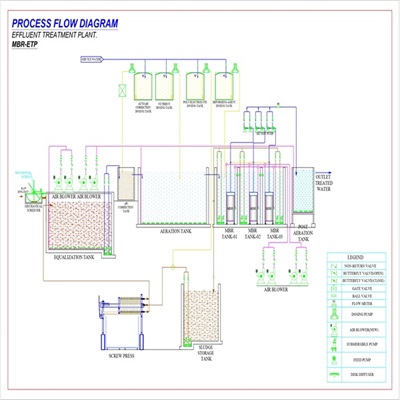

Membrane Bioreactors (MBRs): MBRs combine biological treatment with membrane filtration. The membranes act as a barrier to separate solids from the treated water, providing a high level of purification. MBR technology is known for producing high-quality effluent and requires less space compared to conventional systems.

Constructed Wetlands: This eco-friendly approach involves the use of natural processes to treat wastewater. Wetland plants, soil, and microbial activity in the wetland ecosystem help remove pollutants. Constructed wetlands are particularly effective in treating certain types of industrial wastewater.

Sequential Batch Reactors (SBRs): SBRs are a type of activated sludge process where treatment occurs in batches. The system operates in cycles, including filling, reacting, settling, and decanting phases. SBRs offer flexibility in managing variations in influent flow and load.

Ozonation: Ozonation involves the use of ozone, a powerful oxidizing agent, to break down and remove pollutants from wastewater. This advanced oxidation process is effective in treating industrial effluents containing persistent organic pollutants.

Reverse Osmosis (RO): RO is a membrane-based technology that utilizes semi-permeable membranes to separate contaminants from water. It is commonly employed for desalination and treating water with high levels of salts and dissolved solids.

Green Genesis Engineering Limited is among the top manufacturers of wastewater treatment plants. If you have any concerns regarding the establishment or management of a wastewater treatment plant, please feel free to contact us. We are here to assist you with your concerns. You can call us at +8801933-302535 or email us at karim@greengenesisbd.com.